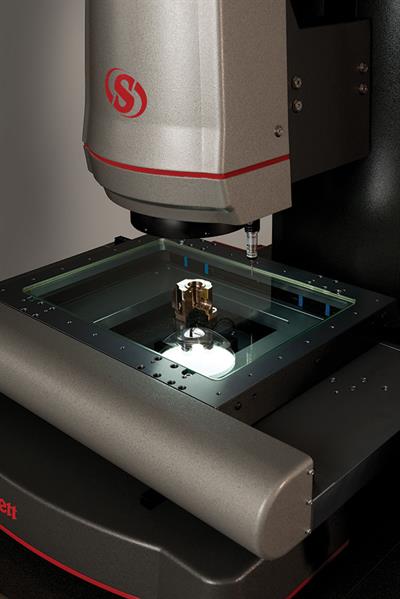

ATHOL, MA U.S.A. (February 1, 2021) - The L.S. Starrett Company is announcing the enhancement of the AVR300 Multi-Sensor Vision System, with a 0.14 magnification lens featuring the largest field of view to date for Starrett on the AVR Series at 2.36" x 1.90" (60 mm x 48 mm). For greater efficiency and accuracy, more of the part can be viewed in every image on the new AVR-FOV 0.14X system. Due to “superimage” technology, which allows multiple images to be stitched together to form one larger image, together with the system’s touch probe technology, the AVR-FOV 0.14X can accurately inspect a wide range of features on large or complex parts, as well as on multiple small parts.

The AVR-FOV 0.14X automated part programs deliver accurate results to the micron level in a matter of seconds with “Go/ No-Go” tolerance zones, and data are provided in one easy-to-interpret report. These features allow metrology users in manufacturing facilities or QC labs to produce accurate, fast, and repeatable results.

"Building on the success of the AVR300 multi-sensor system, now customers can measure and inspect a wider range of parts, including those that are complex with intricate features," said Mark Arenal, General Manager, Starrett Metrology Division, "The interface on the AVR-FOV 0.14X is user friendly and intuitive so all users, including operators right on the shop floor, can complete the inspection process."

Equipped with the M3 software package from MetLogix, a traditional mouse as well as a touchscreen monitor make user interaction easy and intuitive. Auto part recognition enables creating a part measurement program that comprises the desired features of a part for inspection, which can automatically be saved in the system or to a network. Programmable light output options can be built into the program as defined steps, including being called up as the part recognition program initiates. Once the program is created, placing that part within the camera’s field-of-view allows for the saved program to initiate and run the inspection. A Renishaw Touch Probe may also be utilized for quick acquisition of discreet points along a part’s profile as well as Z-axis measurements.

The AVR-FOV 0.14X has an X-Y-Z travel of 12" x 8" x 8" (300mm x 200mm x 200mm). The Starrett AVR-FOV 0.14X Multi-Sensor Vision System is made in the U.S.A.

Click here for more information about the AVR-FOV 0.14X, and click here to view video.